CARBIDE COATED PARTS

Did you know that...

- Mølbro produce the carbide coated wearing parts in a computer controlled welding process

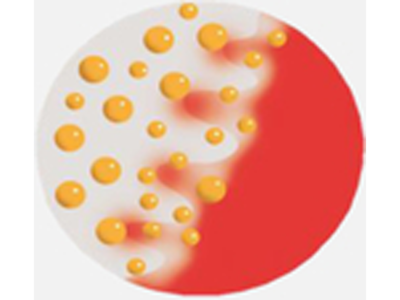

- Mølbro is using a matrix of different carbides, such as tungsten or niobium in different sizes

- Mølbro uses a special developed and specified powder wire, which is getting weld on with six-axis welding robots to ensure maximum precision

- The coating process resulting in matrix material which have cohesively connection with the base material - this ensures optimal durability of the coating

- Our products coated on the backside of the wearing parts to keep the self-sharpening effect of the product and to use the positive effect of wear

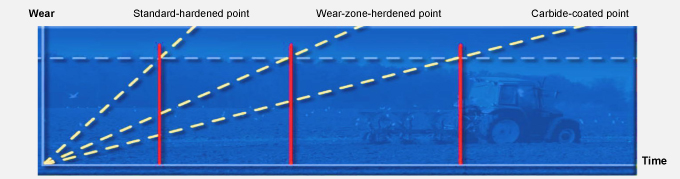

- The carbide coated wearing parts last much longer than parts without coating and a least reduce your costs

Further information

Please contact Mølbro Production A/S for further information about our catalog material